Inkjet Printing

Although inkjets were available in the 1980s, it was only in the 1990s that prices dropped enough to bring the technology to the high street. Canon claims to have invented what it terms "bubble jet" technology in 1977, when a researcher accidentally touched an ink-filled syringe with a hot soldering iron. The heat forced a drop of ink out of the needle and so began the development of a new printing method.

Traditionally, inkjets have had one massive attraction over laser printers; their ability to produce colour, and that is what makes them so popular with home users. Since the late 1990s, when the price of colour laser printers began to reach levels which made them viable for home users, this advantage has been less definitive. However, in that time the development of inkjets capable of photographic-quality output has done much to help them retain their advantage in the realm of colour.

The down side is that although inkjets are generally cheaper to buy than lasers, they are more expensive to maintain. Cartridges need to be changed more frequently and the special coated paper required to produce high-quality output is very expensive. When it comes to comparing the cost per page, inkjets work out about ten times more expensive than laser printers.

Operation

Inkjet printing, like laser printing, is a non-impact method. Ink is emitted from nozzles as they pass over a variety of possible media, and the operation of an inkjet printer is easy to visualise: liquid ink in various colours being squirted at the paper to build up an image. A print head scans the page in horizontal strips, using a motor assembly to move it from left to right and back, as another motor assembly rolls the paper in vertical steps. A strip of the image is printed, then the paper moves on, ready for the next strip. To speed things up, the print head doesn"t print just a single row of pixels in each pass, but a vertical row of pixels at a time.

On ordinary inkjets, the print head takes about half a second to print a strip across a page. Since A4 paper is about 8.5in wide and inkjets operate at a minimum of 300dpi, this means there are at least 2,475 dots across the page. The print head has, therefore, about 1/5000th of a second to respond as to whether or not a dot needs printing. In the future, fabrication advances will allow bigger print-heads with more nozzles firing at faster frequencies, delivering native resolutions of up to 1200dpi and print speeds approaching those of current colour laser printers (3 to 4ppm in colour, 12 to 14ppm in monochrome).

There are several types of inkjet technology but the most common is "drop on demand" (DOD). This works by squirting small droplets of ink onto paper, through tiny nozzles: like turning a hosepipe on and off 5,000 times a second. The amount of ink propelled onto the page is determined by the driver software that dictates which nozzles shoot droplets, and when.

The nozzles used in inkjet printers are hair fine and on early models they became easily clogged. On modern inkjet printers this is rarely a problem, but changing cartridges can still be messy on some machines. Another problem with inkjet technology is a tendency for the ink to smudge immediately after printing, but this, too, has improved drastically during the past few years with the development of new ink compositions.

Thermal technology

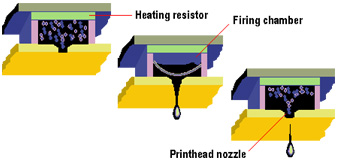

Most non-Epson inkjets use thermal technology, whereby heat is used to fire ink onto the paper. There are three main stages with this method. The squirt is initiated by heating the ink to create a bubble until the pressure forces it to burst and hit the paper. The bubble then collapses as the element cools, and the resulting vacuum draws ink from the reservoir to replace the ink that was ejected. This is the method favoured by Canon and Hewlett-Packard.

Most non-Epson inkjets use thermal technology, whereby heat is used to fire ink onto the paper. There are three main stages with this method. The squirt is initiated by heating the ink to create a bubble until the pressure forces it to burst and hit the paper. The bubble then collapses as the element cools, and the resulting vacuum draws ink from the reservoir to replace the ink that was ejected. This is the method favoured by Canon and Hewlett-Packard.

Thermal technology imposes certain limitations on the printing process in that whatever type of ink is used, it must be resistant to heat because the firing process is heat-based. The use of heat in thermal printers creates a need for a cooling process as well, which levies a small time overhead on the printing process.

Tiny heating elements are used to eject ink droplets from the print-head's nozzles. Today's thermal inkjets have print heads containing between 300 and 600 nozzles in total, each about the diameter of a human hair (approx. 70 microns). These deliver drop volumes of around 8 - 10 picolitres (a picolitre is a million millionth of a litre), and dot sizes of between 50 and 60 microns in diameter. By comparison, the smallest dot size visible to the naked eye is around 30 microns. Dye-based cyan, magenta and yellow inks are normally delivered via a combined CMY print-head. Several small colour ink drops - typically between four and eight - can be combined to deliver a variable dot size, a bigger palette of non-halftoned colours and smoother halftones. Black ink, which is generally based on bigger pigment molecules, is delivered from a separate print-head in larger drop volumes of around 35pl.

Tiny heating elements are used to eject ink droplets from the print-head's nozzles. Today's thermal inkjets have print heads containing between 300 and 600 nozzles in total, each about the diameter of a human hair (approx. 70 microns). These deliver drop volumes of around 8 - 10 picolitres (a picolitre is a million millionth of a litre), and dot sizes of between 50 and 60 microns in diameter. By comparison, the smallest dot size visible to the naked eye is around 30 microns. Dye-based cyan, magenta and yellow inks are normally delivered via a combined CMY print-head. Several small colour ink drops - typically between four and eight - can be combined to deliver a variable dot size, a bigger palette of non-halftoned colours and smoother halftones. Black ink, which is generally based on bigger pigment molecules, is delivered from a separate print-head in larger drop volumes of around 35pl.

Nozzle density, corresponding to the printer's native resolution, varies between 300 and 600dpi, with enhanced resolutions of 1200dpi increasingly available. Print speed is chiefly a function of the frequency with which the nozzles can be made to fire ink drops and the width of the swath printed by the print-head. Typically this is around 12MHz and half an inch respectively, giving print speeds of between 4 to 8ppm (pages per minute) for monochrome text and 2 to 4ppm for colour text and graphics.

Piezo-electric technology

Epson's proprietary inkjet technology uses a piezo crystal at the back of the ink reservoir. This is rather like a loudspeaker cone - it flexes when an electric current flows through it. So, whenever a dot is required, a current is applied to the piezo element, the element flexes and in so doing forces a drop of ink out of the nozzle.

Epson's proprietary inkjet technology uses a piezo crystal at the back of the ink reservoir. This is rather like a loudspeaker cone - it flexes when an electric current flows through it. So, whenever a dot is required, a current is applied to the piezo element, the element flexes and in so doing forces a drop of ink out of the nozzle.

There are several advantages to the piezo method. The process allows more control over the shape and size of ink droplet release. The tiny fluctuations in the crystal allow for smaller droplet sizes and hence higher nozzle density. Also, unlike with thermal technology, the ink does not have to be heated and cooled between each cycle. This saves time, and the ink itself is tailored more for its absorption properties than its ability to withstand high temperatures. This allows more freedom for developing new chemical properties in inks.

Epson's latest mainstream inkjets have black print-heads with 128 nozzles and colour (CMY) print-heads with 192 nozzles (64 for each colour), addressing a native resolution of 720 by 720dpi. Because the piezo process can deliver small and perfectly formed dots with high accuracy, Epson is able to offer an enhanced resolution of 1440 by 720dpi - although this is achieved by the print-head making two passes, with a consequent reduction in print speed. The tailored inks Epson has developed for use with its piezo technology are solvent-based and extremely quick-drying. They penetrate the paper and maintain their shape rather than spreading out on the surface and causing dots to interact with one another. The result is extremely good print quality, especially on coated or glossy paper.

Epson's latest mainstream inkjets have black print-heads with 128 nozzles and colour (CMY) print-heads with 192 nozzles (64 for each colour), addressing a native resolution of 720 by 720dpi. Because the piezo process can deliver small and perfectly formed dots with high accuracy, Epson is able to offer an enhanced resolution of 1440 by 720dpi - although this is achieved by the print-head making two passes, with a consequent reduction in print speed. The tailored inks Epson has developed for use with its piezo technology are solvent-based and extremely quick-drying. They penetrate the paper and maintain their shape rather than spreading out on the surface and causing dots to interact with one another. The result is extremely good print quality, especially on coated or glossy paper.

Colour perception

Visible light falls between 380nm (violet) and 780nm (red) on the electromagnetic spectrum, sandwiched between ultraviolet and infrared. White light comprises approximately equal proportions of all the visible wavelengths, and when this shine on or through an object, some wavelengths are absorbed and others are reflected or transmitted. It's the reflected or transmitted light that gives the object its perceived colour. Leaves, for example, are their familiar colour because chlorophyll absorbs light at the blue and red ends of the spectrum and reflects the green part in the middle.

The "temperature" of the light source, measured in Kelvin (K), affects an object's perceived colour. White light, as emitted by the fluorescent lamps in a viewing box or by a photographer's flashlight, has an even distribution of wavelengths, corresponding to a temperature of around 6,000K, and doesn't distort colours. Standard light bulbs, however, emit less light from the blue end of the spectrum, corresponding to a temperature of around 3,000K, and cause objects to appear more yellow.

Humans perceive colour via a layer of light-sensitive cells on the back of the eye called the retina. The key retinal cells are the cones that contain photo-pigments that render them sensitive to red, green or blue light (the other light-sensitive cells, the rods, are only activated in dim light). Light passing through the eye is regulated by the iris and focused by the lens onto the retina, where cones are stimulated by the relevant wavelengths. Signals from the millions of cones are passed via the optic nerve to the brain, which assembles them into a colour image.

Creating colour

Creating colour accurately on paper has been one of the major areas of research in colour printing. Like monitors, printers closely position different amounts of key primary colours which, from a distance, merge to form any colour; this process is known as dithering.

Monitors and printers do this slightly differently however because monitors are light sources, whereas the output from printers reflects light. So, monitors mix the light from phosphors made of the primary additive colours: red, green and blue (RGB), while printers use inks made of the primary subtractive colours: cyan, magenta and yellow (CMY). White light is absorbed by the coloured inks, reflecting the desired colour. In each case, the basic primary colours are dithered to form the entire spectrum. Dithering breaks a colour pixel into an array of dots so that each dot is made up of one of the basic colours or left blank.

The reproduction of colour from the monitor to the printer output is also a major area of research known as colour-matching. Colours vary from monitor to monitor and the colours on the printed page do not always match up with what is displayed on-screen. The colour generated on the printed page is dependent on the colour system used and the particular printer model; not by the colours shown on the monitor. Printer manufacturers have put lots of money into the research of accurate monitor/printer colour-matching.

Modern inkjets are able to print in colour and black and white, but the way they switch between the two modes varies between different models. The basic design is determined by the number of inks in the machine. Printers containing four colours - cyan, yellow, magenta, and black (CMYK) - can switch between black and white text and colour images all on the same page with no problem. Printers equipped with only three colours, can"t.

Many of the cheaper inkjet models have room for only one cartridge. You can set them up with a black ink cartridge for monochrome printing, or a three-colour cartridge (CMY) for colour printing, but you can"t set them up for both at the same time. This makes a big difference to the operation of the printer. Each time you want to change from black and white to colour, you must physically swap over the cartridges. When you use black on a colour page, it will be made up from the three colours, which tends to result in an unsatisfactory dark green or grey colour usually referred to as composite black. However, the composite black produced by current inkjet printers is much better than it was a few years ago due to the continual advancements in ink chemistry.

Print quality

The two main determinants of colour print quality are resolution, measured in dots per inch (dpi), and the number of levels or graduations that can be printed per dot. Generally speaking, the higher the resolution and the more levels per dot, the better the overall print quality.

In practice, most printers make a trade-off, some opting for higher resolution and others settling for more levels per dot, the best solution depending on the printer's intended use. Graphic arts professionals, for example, are interested in maximising the number of levels per dot to deliver "photographic" image quality, while general business users will require reasonably high resolution so as to achieve good text quality as well as good image quality.

The simplest type of colour printer is a binary device in which the cyan, magenta, yellow and black dots are either "on" (printed) or "off" (not printed), with no intermediate levels possible. If ink (or toner) dots can be mixed together to make intermediate colours, then a binary CMYK printer can only print eight "solid" colours (cyan, magenta, yellow, red, green and blue, plus black and white). Clearly this isn't a big enough palette to deliver good colour print quality, which is where halftoning comes in.

Halftoning algorithms divide a printer's native dot resolution into a grid of halftone cells and then turn on varying numbers of dots within these cells in order to mimic a variable dot size. By carefully combining cells containing different proportions of CMYK dots, a halftoning printer can "fool" the human eye into seeing a palette of millions of colours rather than just a few.

In continuous tone printing there's an unlimited palette of solid colours. In practice, "unlimited" means 16.7 million colours, which is more than the human eye can distinguish. To achieve this, the printer must be able to create and overlay 256 shades per dot per colour, which obviously requires precise control over dot creation and placement. Continuous tone printing is largely the province of dye sublimation printers. However, all of the mainstream printing technologies can produce multiple shades (usually between 4 and 16) per dot, allowing them to deliver a richer palette of solid colours and smoother halftones. Such devices are referred to as "contone" printers.

Recently, "six-colour" inkjet printers have appeared on the market, specifically targeted at delivering "photographic-quality" output. These devices add two further inks - light cyan and light magenta - to make up for current inkjet technology's inability to create very small (and therefore light) dots. Six-colour inkjets produce more subtle flesh tones and finer colour graduations than standard CMYK devices, but are likely to become unnecessary in the future, when ink drop volumes are expected to shrink to around 2 to 4 picolitres. Smaller drop sizes will also reduce the amount of halftoning required, as a wider range of tiny drops can be combined to create a bigger palette of solid colours.

Long-time market leader Hewlett-Packard has consistently espoused the advantages of improving colour print quality by increasing the number of colours that can be printed on an individual dot rather than simply increasing dpi, arguing that the latter approach both sacrifices speed and causes problems arising from excess ink - especially on plain paper. HP manufactured the first inkjet printer to print more than eight colours (or two drops of ink) on a dot in 1996, it's DeskJet 850C being capable of printing up to four drops of ink on a dot. Over the years it has progressively refined its PhotoREt colour layering technology to the point where, by late 1999, it was capable of producing an extremely small 5pl drop size and up to 29 ink drops per dot - sufficient to represent over 3,500 printable colours per dot.

Read more: http://www.pctechguide.com/index.htm

show prices

Prices and availability are subject to change without notice.The copyright of all art images belongs to the individual artists and Magnolia Editions, Inc.

©2003-2024 Magnolia Editions, Inc. All rights reserved. contact us